How ARTI and Pixelrunner worked together to improve software for mobile autonomous outdoor robots, using 3D SLAM, simulation and localization without GPS.

Logos on the landscape – large and eye-catching advertising

Large-scale prints of logos or messages on grass, asphalt, or even snow are very much in demand. They serve as a great form of advertising or an effective event decoration. Until now, this type of advertising was mainly done at football games and sporting events such as runs or ski races. The only occasions when professional cameras were used for aerial photography.

With the further spread of photo drones, aerial shots are now easier. Landscape printing as a marketing tool is becoming more and more attractive.

Pixelrunner GmbH from Engerwitzdorf specializes in outdoor advertising. They offer an exact, automated, and fully digital printing process using patented spray technology.

About Pixelrunner – “Land Art becomes Brand Art”

Pixelrunner GmbH was founded in 2016 out of the Softwarepark Hagenberg. In the following year, they won the Young Entrepreneur Award. Since then, the team of 5 has already implemented some spectacular projects. Examples are the Erste Bank/Sparkasse advertising campaign during the Vienna City Marathon 2022, which featured a vast #glaubandich lettering across the entire Reichsbrücke. For the Marathon in Berlin, Pixelrunner has been printing the logo on the lawn in front of the Siegessäule for several years.

Landscape printing using the traditional method is a very time-consuming affair. First, before printing, scaled templates have to be produced. Then, the printing area has to be measured very precisely. And finally, the images have to be transferred to the surface by hand with the help of templates.

Pixelrunner, however, has automated the entire process and made it much faster. The automated process includes processing the graphics with a specially developed software solution and applying the logo. But it needs just a fraction of the time when compared to landscape printing with the conventional method. This is particularly advantageous when printing on roads, as these are only ever closed for traffic for a short period before events. Furthermore, the logo is easily removeable after the event, thanks to biodegradable ink.

Pixelrunner and ARTI – a successful technological challenge

But what does large-scale landscape printing have to do with a software start-up for mobile autonomous outdoor robots?

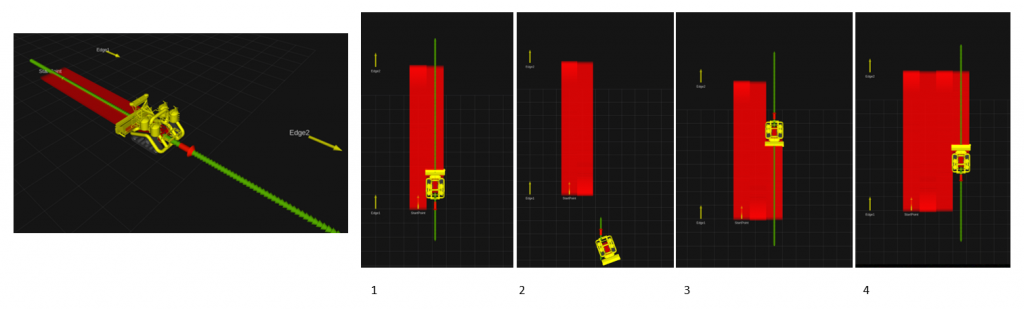

The answer is quite simple: the logo prints autonomously with the robot “Pixelrunner Mk2”. Pixelrunner Mk2 accords to SAE 2 and drives at a 30 m2/minute speed. We at ARTI supported Pixelrunner GmbH in giving the robot precision in localization/positioning and stability in driving behaviour. These features are necessary to apply such large-area graphics (800m2 and larger!) precisely to the surface.

The task given to ARTI was to improve outdoor line following over large areas, using positioning that was not GPS-based. During the development, we at ARTI had to consider the general conditions of the printing process. For example, personnel must monitor the vehicle during printing. The system must be usable worldwide, and the operation must be simple and intuitive. Finally, the printing area must be scalable as desired.

The challenges presented to ARTI for the Pixelrunner project were numerous. They included different uneven surfaces (grass, snow, asphalt, parchment), alternating weather conditions, control of a track-driven vehicle, and the arbitrary expansion of the printable area. ARTI’s chief developer Alexander Buchegger describes the task:

“With Pixelrunner, the aim was to develop an alternative navigation system to the GPS-based one. The vehicle can be used in areas where GPS does not work or does not work accurately enough. The big challenge here is to locate the robot within a few centimeters in uneven terrain, without good reference objects, and to navigate the vehicle so accurately.”

ALEXANDER BUCHEGGER – ARTI CHIEF DEVELOPER

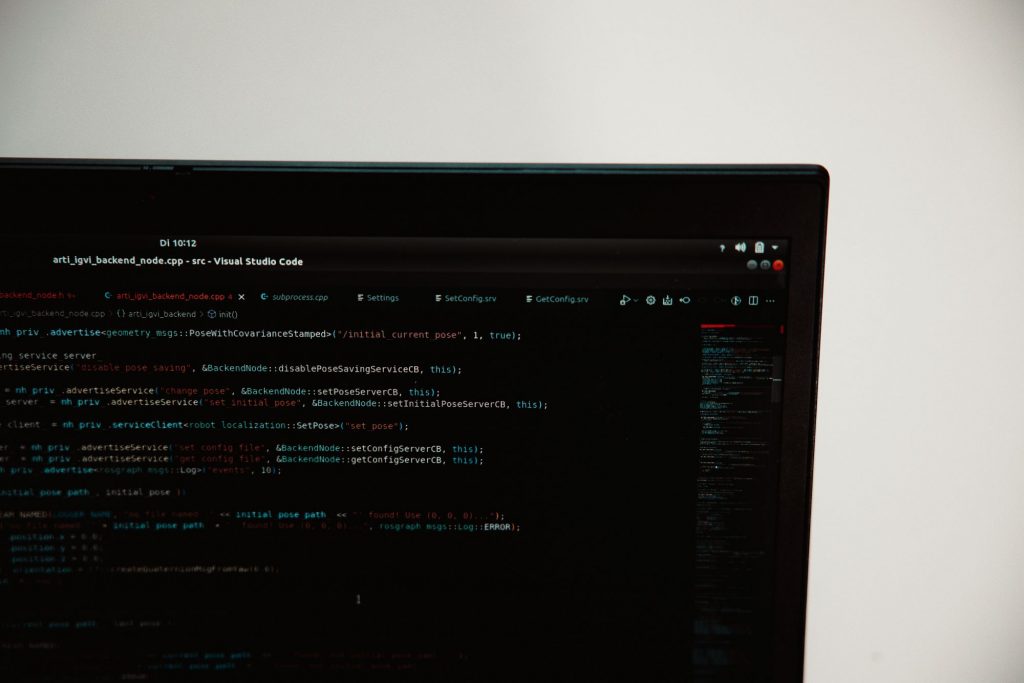

Software methods for autonomous outdoor robots: 3D SLAM and simulation

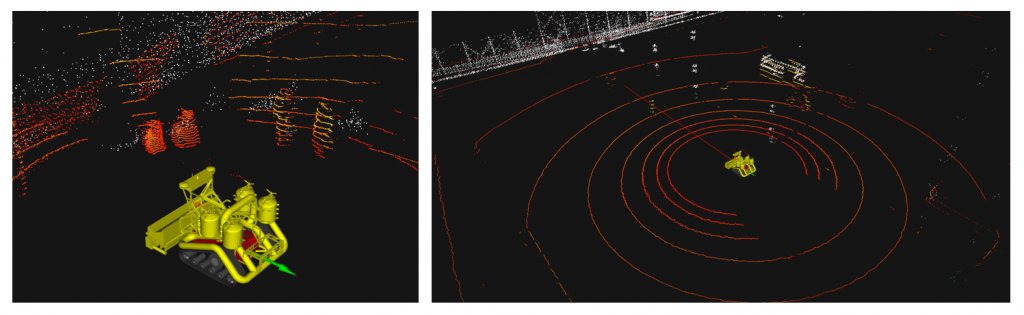

The technical implementation of positioning uses a SLAM approach. This approach involves an Ouster OS1-16 Layer LiDAR scanner on the vehicle and, if necessary, other landmarks. SLAM stands for Simultaneous Localization and Mapping and is a complex technology. It allows the robot to construct or update a map of an unknown environment while at the same time defining and registering its location within that same map. With Pixelrunner, we took this already intricate technology even further. Rather than using the SLAM approach in 2D, we developed a vastly more detailed, state-of-the-art 3D version. This creates an immense difference in the data collected and allows for an even more precise definition of the environment.

In addition, in a digital twin 3D simulation, we run tests about control and sequence, various alternations like repositioning markers, print changes or software updates. This completely transforms the testing phase, making it less work and time intensive than real-world testing. Furthermore, the simulation allows the testing of various scenarios and print sizes. Ultimately, this helps us recognize errors and faulty conditions before they occur. All this contributes to more efficiency and results in a higher-quality final product.

Raphael Hoheneder, the ARTI expert for navigation of autonomous outdoor robots, adds:

“In the Pixelrunner project, we implemented the localization employing LiDAR as well as the precise tracing of parallel lines for printing. And we developed the interfaces to the hardware and the user application. The biggest challenges were stabilizing the localization and the speed, so that clean and smooth driving is possible.”

RAPHAEL HOHENEDER – ARTI EXPERT FOR OUTDOOR NAVIGATION

The challenges from the Pixelrunner perspective

One of the biggest challenges on the Pixelrunner side is the constantly changing environment for every new printing job. The team tries to get an overview in advance via satellite images, but this is only possible to a limited extent. In addition, there are external factors such as weather and light conditions.

Since time pressure also plays a significant role, there is not enough time for a typical deployment routine and markers’ corresponding setup, calibration, and positioning.

For Pixelrunner, the following applies quite clearly: The print has top priority. Therefore, no stops may occur during printing, negatively influencing the result. The robot must therefore be able to run through its printing paths undisturbed.

Pixelrunner managing director Simon Novy says:

“ARTI’s system enables us to use our technology everywhere – independent of the available GPS signal. We especially appreciate ARTI’s continuous development of the system and professional input. Together we are working on further automating the printing process.”

SIMON NOVY – PIXELRUNNER CEO

About ARTI Software for autonomous outdoor robots – “Make things moving!”

The cooperation with Pixelrunner was a technologically exciting challenge for us at ARTI. It demanded high precision and smooth driving behaviour. We have mastered that challenge and once again proved the excellent applicability of our AI software in the outdoor sector.

What is unique about ARTI software for mobile autonomous outdoor robots is its flexible applicability for various use cases. The software has a modular structure independent of environmental factors and vehicle characteristics. As a result, countless use cases focusing on autonomous locomotion can be solved quickly.

Like those in the Pixelrunner project, outdoor environments differ from indoor environments due to natural conditions such as uneven ground or changing light conditions. They remain a challenging and complex topic in autonomous robotics.

At ARTI, we enjoy projects like this the most. They allow us to use the ARTI AI software modules (AI Kits) and combine them with our knowledge and experience in robotics. This way we develop innovative new products with our customers and improve existing ones. Staying true to our motto, “Make things moving!” we literally want to set things in motion and thrive on innovation and automation.

Further links, videos and press content: