The Start

Autonomous racing is a branch of fully automated driving competitions, where the objective is to compete against other automated vehicles or human drivers on a racetrack through various driving challenges. It is a cutting-edge sports event that incorporates the latest advancements in technology and pushes both the vehicles and the software to their limits. By doing this, autonomous racing also derives valuable insights, which afterwards often find application in other areas and are utilized to make vehicles safer and more reliable for the wider masses.

To participate in this type of competition and help advance the field of autonomous racing by improving existing technology, the Autonomous Racing Graz (ARG) team was founded. Comprised of researchers, students, and postdocs from the Institute of Automation and Control at the Graz University of Technology and the Virtual Vehicle Research (both in Graz, Austria), the team boasts members experienced in automotive sensors, software, and control. They aim to demonstrate the capabilities of autonomous driving in challenging conditions (high speeds, high lateral dynamics, adverse weather conditions) and prove that serious research and fun can go hand in hand. The ARG’s objective is to refine the existing software stack while working on three main challenges in autonomous racing: performance, precision and wheel-to-wheel racing.

Two of ARTI‘s founders, CEO Konstantin Mautner-Lassnig and CTO Stefan Loigge, have been a part of the ARG team from the very beginning. Their participation in university teams like this one was also one of the factors that led to the founding of ARTI, which has been a partner of ARG ever since.

Competing at Roborace

Ever since its creation, the ARG team’s ultimate goal was to participate in Roborace, the world’s first autonomous competition race series.

Roborace started with the Season Alpha in August 2019. The inaugural event was the localisation challenge, held at the Zala Zone Racetrack in Hungary. Teams were tasked with writing the software to control the car, adapting to both track conditions and challenge regulations. They had to show speed, agility, precision, and accuracy while executing complex manoeuver. The challenge required participants to drive the circuit as fast and as precisely as possible using LiDAR-based localization. The track featured narrow gates marked by cones that had to be passed without collision, in order to avoid time penalties.

By working as a team and putting their knowledge to the test, the ARG team placed second in the competition

Race to the Finish Line

The final event of the Season Alpha was the Performance and Precision Challenge in November 2019.

As one of the big highlights, the Performance and Precision Challenge featured the debut of the Roborace DevBot 2.0, a cutting-edge prototype vehicle used as a test platform for the teams’ autonomous systems. Equipped with LIDAR, radar, and cameras, DevBot 2.0 was able to navigate the track with pinpoint accuracy. This was the first opportunity for the public to see driverless electric racing cars in action.

The challenge showcased thrilling on-track battles, as the driverless cars operated by the participating teams fiercely competed for the lead. The intense competition required teams to make quick decisions to stay ahead. Despite the pressure, the cars functioned seamlessly, highlighting the technology’s potential for the future of racing. The competition consisted of 6 laps featuring high-speed sections and tight gates, which the team successfully navigated to finish in first place.

In the first session, the ARG team achieved a lap time of 1 min 37.440 sec. In the second session, they achieved a lap time of 1 min 17.830 sec. This significant difference of nearly 20 seconds was achieved by further optimizing the software and pushing the limits of vehicle dynamics.

This lap difference is also what ultimately made the ARG team secure a victory in the challenge.

Overall, the Roborace Season Alpha Performance and Precision Challenge was a huge success, demonstrating the maturity of the technology for safe and exciting races. The teams and organizers showed the viability of the series, demonstrating Roborace as a pioneer in autonomous motorsports. It was made clear that the future of such innovative sports holds great promise.

Exploring the Technology Behind the Success

When it comes to autonomous driving, there are only a few open-source software stacks, one of them being Autoware. It is a well-known open-source software offering a comprehensive solution for self-driving vehicles. It encompasses modules for localization, detection, prediction, planning as well as control and is built on top of the Robot Operating System (ROS) along with some other established open-source libraries. Autoware integrates various software components and offers easy-to-use interfaces and tools for efficient setup. While primarily designed for urban environments, it can also partially support highways and freeways.

Autoware is the software stack used by the ARG team.

Mapping

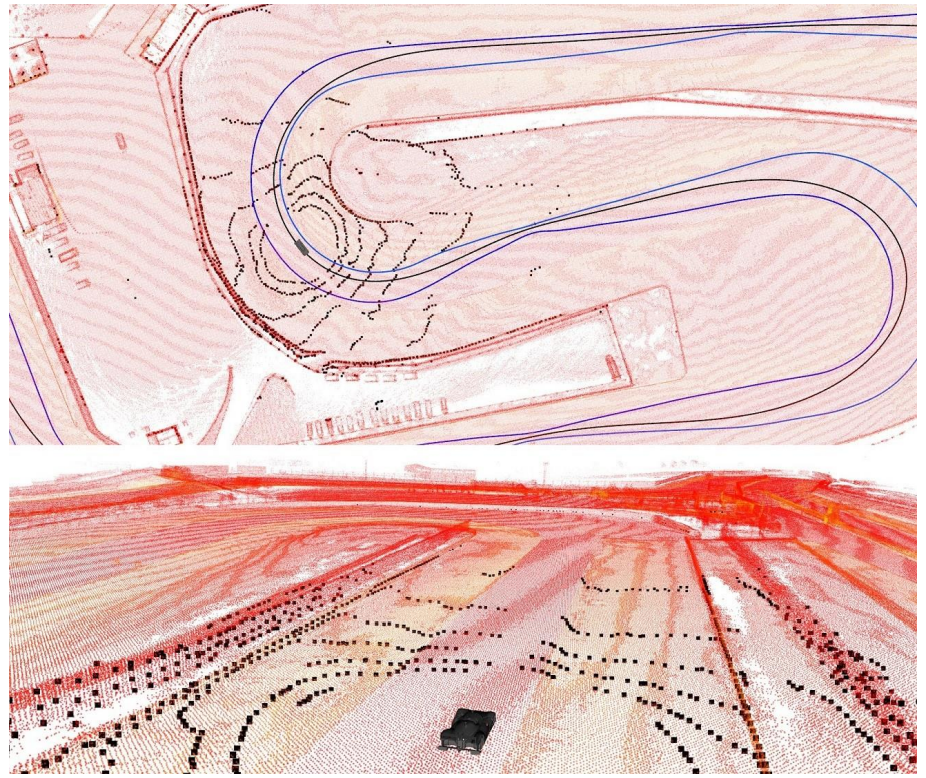

Accurately mapping a track is the crucial key to enabling localization and therefore racing on a specific circuit. However, creating a map with such high accuracy is still a challenging and often ill-defined process, especially when obstacles like fences or difficult-to-detect materials are present. Balancing map size and quality is crucial because of the impact on data volume and processing speed. Despite this, a full 3D map offers significant advantages in various fields. Localization benefits from the full map information to produce a more accurate and stable position. A 3D approach, which the ARG team took, is superior to 2D methods.

Having the data of exact racetrack borders and passages can enhance the quality of raceline computation. Furthermore, height data is essential for proper data and sensor association and alignment, particularly in the sensor fusion between GPS measurements and LiDAR-predicted positions. With this information, the point cloud map is created using the NDT algorithm and processed in RVIZ to obtain a 3D point cloud. Defining the inner and outer borders by hand is necessary as racetrack boundaries vary from race to race, which would make automation less time-effective.

Racing line generation

The gained layout of the racetrack is used to create a reference line, which is later used to optimize the racing line. The reference line generation process involves eight steps:

1. DATA READING AND DUPLICATES REMOVAL | 2. LINEAR INTERPOLATION | 3. DISTANCE MATRIX CALCULATION | 4. PAIR FINDING

5. REFERENCE LINE CALCULATION | 6. REFERENCE LINE SMOOTHING | 7. INCLUSION OF CORNER POINTS | 8. INCLUSION OF GATE POINTS

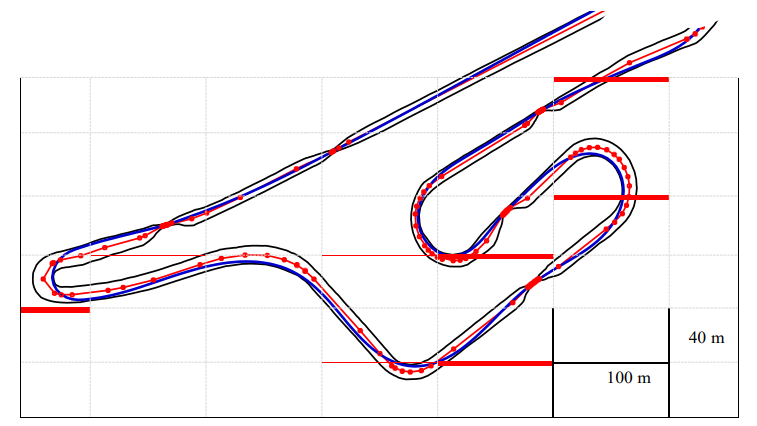

For race line optimization, the team used the minimum curvature trajectory planning approach, a method used in motion planning and control of autonomous vehicles. It involves generating a smooth trajectory with minimum curvature (i.e., a path that changes direction as gradually as possible) that takes the vehicle from a start point to an endpoint while avoiding obstacles and satisfying other constraints such as velocity and acceleration limits.

Due to its smooth and limited peak curvature, it works great for real-world applications. The minimum curvature path is generated using an iterative quadratic programming (QP) formulation. This results in a smooth reference line, which is then used as an input for the algorithm that calculates the optimal racing line.

“The challenging aspect lies in achieving precise robotic movement without clear reference markers, even when the robot’s positioning has to be accurate within a few centimeters. This situation directly demonstrates how fine tuning the software significantly and directly influences the robot’s performance on the racetrack.”

STEFAN LOIGGE – ARTI CTO

(ARG – SOFTWARE STACK, DATA RECORDING AND POST PROCESSING)

2D versus 3D

The data of the outer points of the racetrack was acquired with a special roller, equipped with a LiDAR sensor, that traversed the racetrack. This had to be done for both the racetrack’s left and right border. The collected data was then provided to the teams.

Rather than using the traditional 2D method, the ARG team opted for the much more advanced 3D mapping technology. They used the provided points and transcended them into a 3D point cloud, vastly improving the point map and allowing for an even more precise definition of the racetrack parameters. This mapping method allowed the team to surpass the limitations of 2D data and gain a competitive advantage, leading to superior positioning on the track.

This effort is unique to the ARG team and ultimately played a role in their success.

LiDAR Distortion Correction

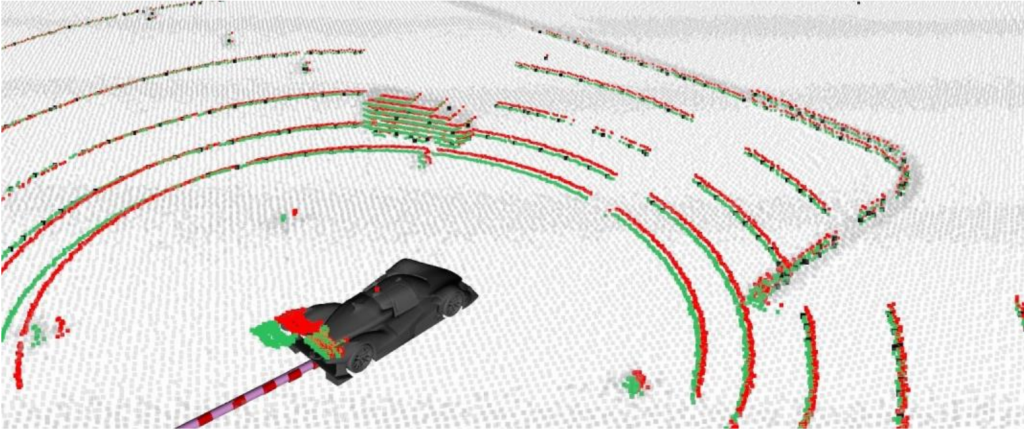

While scanning, sensors take multiple individual measurements at various time points to cover a specific field of view. LiDAR sensors typically provide data in the form of a single point cloud, which is generated after a complete scan. All points in this cloud refer to the same origin, the sensor’s position.

However, when the sensor moves during the scan process, individual measurements correspond to globally different reference locations, leading to errors in distance and direction. This distortion, which increases with speed and turn rate, results in inaccuracies in the measurement and affects localization performance. To correct this distortion, odometry information is used to provide accurate localization.

The image above illustrates the impact of LiDAR distortion and its subsequent correction. It features an offline-generated map depicted in grey, LiDAR measurements marked in red and the resulting corrected point cloud represented in green. This demonstrates the process of addressing LiDAR distortions, in order to refine and enhance the accuracy of point cloud data.

Localization

The algorithm used for mapping and localization within Autoware is the normal distribution transform (NDT), which makes use of LiDAR data as the primary input. The algorithm works by comparing live measurements to previous recordings or a full-scale point cloud map, creating a reference point cloud map divided into 3D boxes with individual probability distributions. Certain aspects like environmental changes can affect the matching quality, since the algorithm searches for similarities during alignment. To address this issue, probability density functions are used, which allow for a “near match” and therefore improve alignment and at the same time address the issue of outliers.

location on the racetrack © ARG

Future outlook

In May 2022, Arrival, the company behind Roborace, announced the end for the series, but also expressed their hope of finding alternative funding in the future. Following this decision, some similar formats emerged, like for instance the Indy Autonomous Challenge (IAC), which underscores the interest and potential in autonomous racing.

By bringing together the community of researchers, engineers, and enthusiasts, events like Roborace serve not only as platforms for technological exhibition but also provide testing grounds for the advancement of autonomous vehicle technologies. Through rigorous competition, they foster a hotbed of innovation in software precision, vehicle performance, and system reliability, accelerating the evolution of self-driving capabilities.

Beyond their technical contributions, these series captivate a global audience, inspiring a future generation of engineers, programmers, and visionaries with the thrilling possibilities of autonomous technology, which is why we at ARTI hope to see more developments in this area in the future.

Further links, videos and press content: