In the world of robotics, simulations play a fundamental role. They allow researchers and engineers to test ideas, validate performance, and optimize algorithms, all without needing to physically operate a robot. This is not only faster and more efficient but also safer and significantly less expensive than real-world testing. In many cases, real-world experiments may be impractical due to time constraints, high risk, or the wear and tear on physical components. That’s why simulations have become essential tools in robotics research and development.

Why Use Simulators in Navigation?

When it comes to autonomous navigation, simulators help us in many ways. They are used to:

- Simulate navigation paths and test how robots follow them.

- Optimize these paths to make the robot faster or more accurate.

- Recreate data collected from real-world trials to study robot behavior in a repeatable way.

- Visualize robots in realistic environments for development.

- Simulate the sensors onboard the robot, including how they handle noise or uncertainty.

In short, simulators allow us to study and improve robots under controlled conditions before deploying them in the real world.

The Importance of a Good Simulator

Many simulators model both the environment and the robot itself. Some focus on physical aspects like mass, friction, inertia, and torque. Others emphasize kinematic behavior, such as how the robot moves, turns, or reacts to control commands.

In autonomous navigation, it is crucial that simulators closely replicate how a robot behaves in the real world. This includes accurately modeling sensors, the robot’s structure, and its interaction with the environment. Most simulators offer a wide range of tunable parameters. Given the advantage of faster testing in virtual environments, a common approach in robotics is to use these simulators not just for experimentation, but also to fine-tune parameters using optimization algorithms. Once optimized, these parameter values are transferred to the real robot.

However, here’s the challenge: if the simulator is not properly calibrated, meaning it does not properly reflect the real-world behavior of the robot, then any parameters optimized in the virtual environment may not perform well when applied to the actual system. That’s exactly where our work comes in.

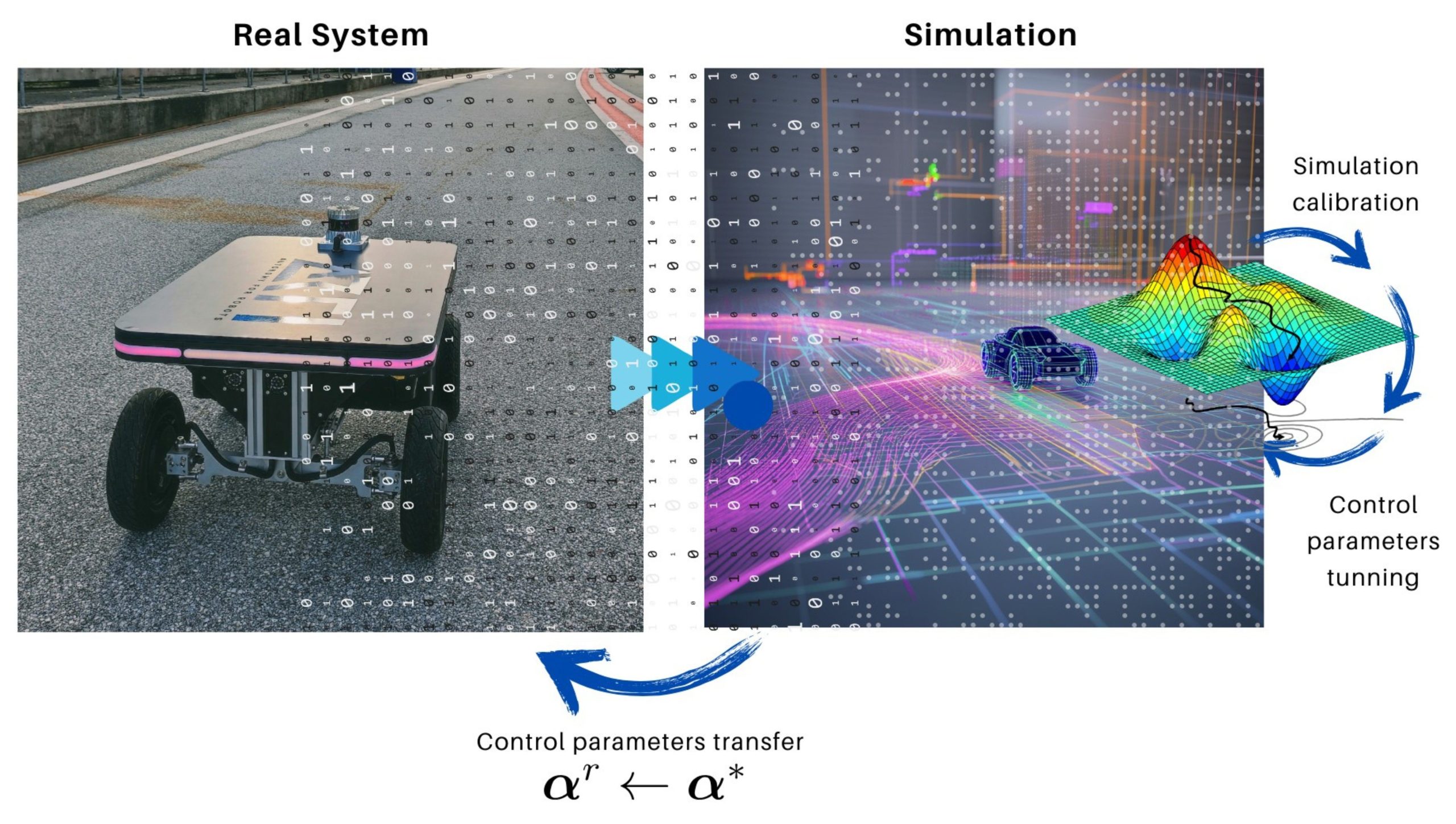

Our Approach

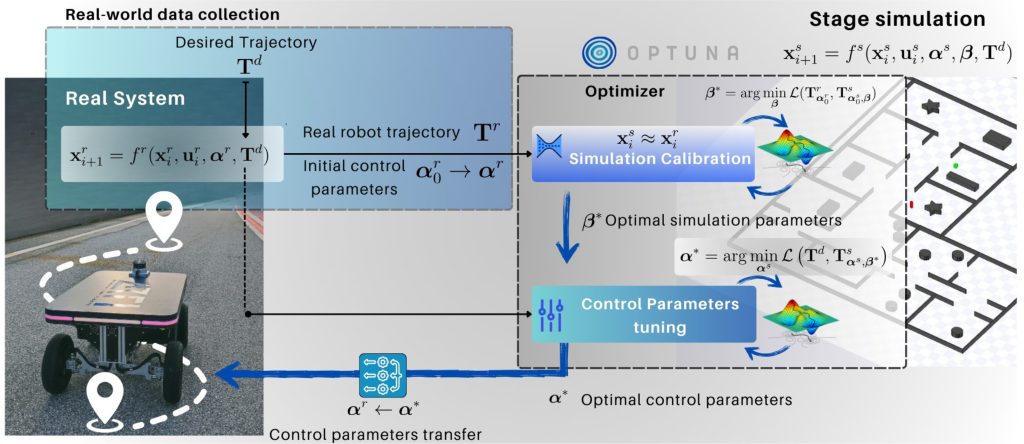

In this study, we propose an optimization-based method that makes simulations more useful for tuning a robot’s navigation controller. We focus on a widely used control method called the Stanley controller, which helps a robot follow a desired path. Our approach follows these main steps:

- Data Collection: First, we create representative scenarios in which the robot follows specific paths using default control parameters. During this process, we collect a small but representative set of real-world data. This includes the robot’s position over time, tracking errors (how far it deviates from the desired path), velocity, acceleration, and other relevant metrics. The type of data we collect depends on the specific parameters we aim to optimize.

- Simulation Calibration: Next, we use the collected data as a reference to adjust the simulator so that it mimics the real robot’s behavior as closely as possible. To do this, we apply optimization algorithms that fine-tune the simulation’s internal parameters. This step is critical, by calibrating the simulator, we ensure that any improvements made in the virtual environment will likely translate well to the real world.

- Controller Optimization: Once the simulator is well-calibrated, we use it to fine-tune the Stanley controller’s parameters. This helps the robot follow its path more accurately and minimizes tracking errors, all without the need to test every variation directly on the real robot.

- Real-World Transfer: Finally, after optimizing the control parameters in simulation and verifying improved performance, we transfer the optimized values to the real robot. This step allows us to benefit from the efficiency of simulation while still achieving reliable performance in the real world.

The following diagram summarizes the steps outlined above.

Achieved improvements

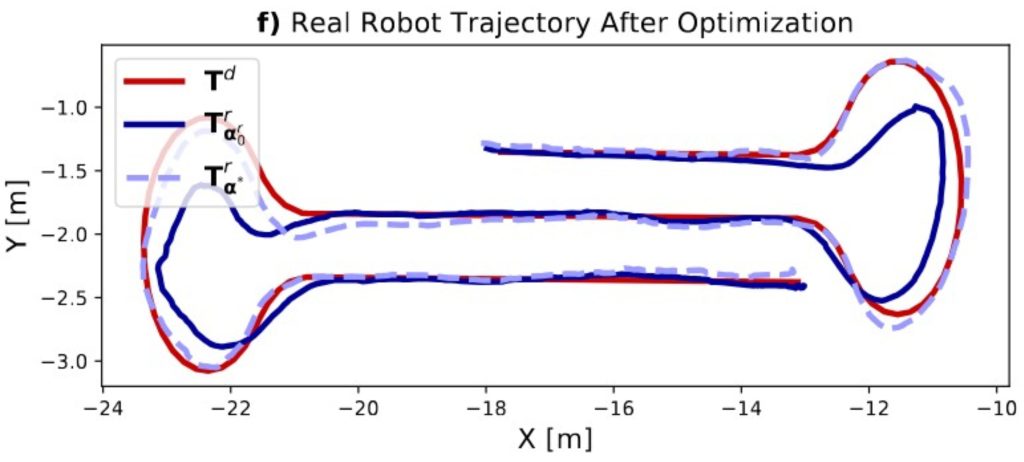

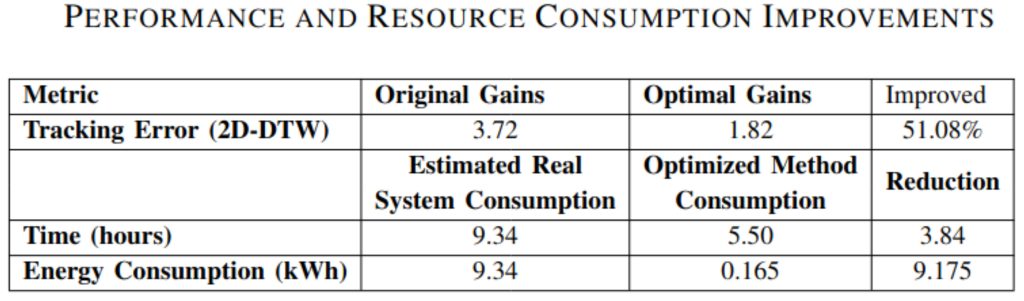

In the following figure, the red line represents the desired trajectory the robot is supposed to follow. The solid dark blue line shows the robot’s actual path before fine-tuning the control parameters, that is, before applying our proposed method. The dotted purple line shows the robot’s trajectory after applying our method. Our approach successfully reduced the tracking error by up to 51%.

Additionally, our approach helped us save approximately 3.84 hours of work compared to performing the same fine-tuning process directly on the real robot. This does not include the extra effort that would have been required from a user to manually conduct and supervise each test, even if the process had already been optimized. Furthermore, we reduced energy consumption by about 9.1 kWh by running the optimization on a computer rather than on the physical robot. On top of that, our method also avoided mechanical wear on the robot’s components, an important factor that, while not quantified, contributes to long-term maintenance and cost savings

For more details about this work, please refer to:

Perez-Villeda, H., Mühlbacher, C., & Mautner-Lassnig, K. Simulation-Driven Optimization of Stanley Controller Gains for Enhanced Tracking in Autonomous Navigation Robots. In Proceedings of the Austrian Robotics Workshop, p. 85, 2025. Click here to view the paper